Chocolate Trends

What Makes Great Chocolate?

There’s chocolate, and then there is the chocolate that makes you STOP and close your eyes to savor the bite before you’re even aware you’re doing it. At Marich, it’s our mission to produce great chocolate, and we believe that it comes down to 5 aspects: the ingredients, the growers, the process of making cocoa, the tempering, and the dedication of craftsmanship.

So let’s break down those 5 aspects that go into making great chocolate.

1. The Ingredients

Our founders were raised to appreciate quality and artisanship in all things, particularly in the chocolate we use (and eat). We aspire to meet and surpass the highest standards, and that’s reflected in the ingredients used in our chocolate.

- Cocoa mass and cocoa butter are the real stars of the show. Cocoa mass brings the flavor, depth, and character, while cocoa butter plays a role in the texture, richness, and also flavor of our chocolates.

- Cane sugar is the sweetening agent for our chocolates. We always use non-GMO cane sugar and in our experience, is the superior sweetener.

- Sunflower Lecithin comes from dehydrated sunflower and acts as a gum that brings all ingredients together to “emulsify” them.

- Vanilla is used to add warmth and roundness to the flavor, we use vanilla as nature intended and stay away from an artificial flavoring.

- Whole Milk goes into our milk chocolate while our dark chocolate has a small amount of butter and oil for added richness and texture.

As chocolatiers, we believe in the power of simplicity. We stick to pure and minimal ingredients so you get rewarded with the taste of real chocolate.

2. The Source and Growers

Our chocolate is only as good as our growers and suppliers, and we proudly source Fair Trade cocoa.

Sourcing plays a number of key roles in the quality of chocolate including: relationships, values, commitments to industry leading quality, and ethical sourcing. Conscious sourcing also affects the quality of the cacao grown and the level of expertise and dedication in the handling and processing.

At Marich we begin by working with suppliers that share our commitment to quality and ones where we have common goals for the mutual benefit of everyone involved.

We have enjoyed lifelong and often multi-generational relationships with many of our suppliers. Built on mutual respect, our partnerships are the foundation of positive day-to-day, year-to-year interactions that extend into enduring friendships.

3. The Process of Making Cocoa

Like wine and coffee, cacao has a terroir – this means that it’s environmental factors like soil, topography, and climate influence the cacao from tree to bean, affecting its outcome. Since these variables are largely uncontrollable, how the cacao bean is processed into cocoa is a vital step in any chocolate making process.

When the cacao bean’s pod is ripe and handpicked, the flavor tastes nothing of chocolate. The outer layer of the bean is sweet and tart while the inside is bitter. The process transforming this bitter fruit into the velvety chocolate you know and love, requires a tremendous amount of care and craftsmanship.

Fermentation is one of the most critical steps after harvest. The beans are put into bins and covered with banana leaves to ferment for up to 4-6 days. Under or over fermenting can quickly have a negative impact on quality and flavor.

Drying, roasting, winnowing, grinding, pressing off, refining, and finally, making chocolate, are all the steps that go into the final product you find at the store.

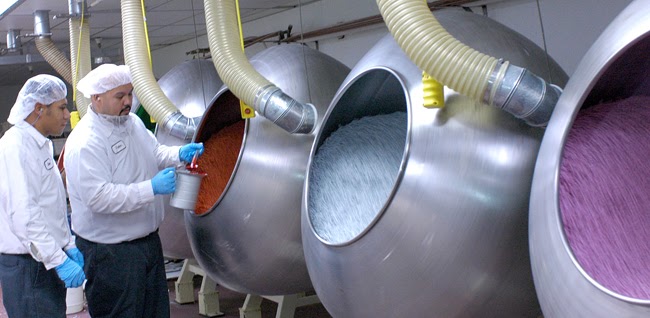

4. The Dedication to Craftsmanship

Every product and craft has a natural speed limit. Exceed that speed limit and we sacrifice taste, texture and overall quality. With chocolate, this is supremely true.

Rush or shortcut any step and the end product will suffer, every time. Making exceptional chocolate requires learning, mastering and respecting the tradition and practices that make a great product every time.

Our candy makers have a deep understanding of the timing, care and expertise required to make premium products. Their skill and dedication to the craft is a great source of pride and are truly masterful artists.

5. The Tempering

Tempering is the heating and cooling of chocolate to create the perfect finished coating. It is near alchemy to get it right and when just slightly off, the result can quickly reach a point of no return. When handled correctly, the difference is remarkable.

Our candy makers control the tempering process to ensure quality and precision. Cocoa butter can crystallize in 4 primary forms: Alpha, Gamma, Beta, and Beta Prime, out of all these forms only beta results in shiny, beautiful, chocolate with a crisp snap to it. To temper correctly, the chocolate has to be brought up to a specific temperature, then cooled down to a second temperature, and finally level off at a temperature in between the two to be able to work with it – and these temperatures are all different for different types of chocolate (milk, dark, white, etc.). The process takes artful love, care and attention to coax the right crystal to the form that gives chocolate the perfect coating.

Mishandle the tempering process and the result is a blotchy, grainy, greyish crumbly chocolate bar. Similar to the one that melts in your car only to solidify into inedible mess.

Our team at Marich believes that we have a responsibility to our customers, growers, stakeholders, and environment. Our products are a reflection of living out this value, and it is shown throughout the entire process of making chocolate, from planting and harvesting to tempering and packaging.